Portable scale with 1% accuracy

You carry the rail scale with you directly to the wagon you need to weigh.

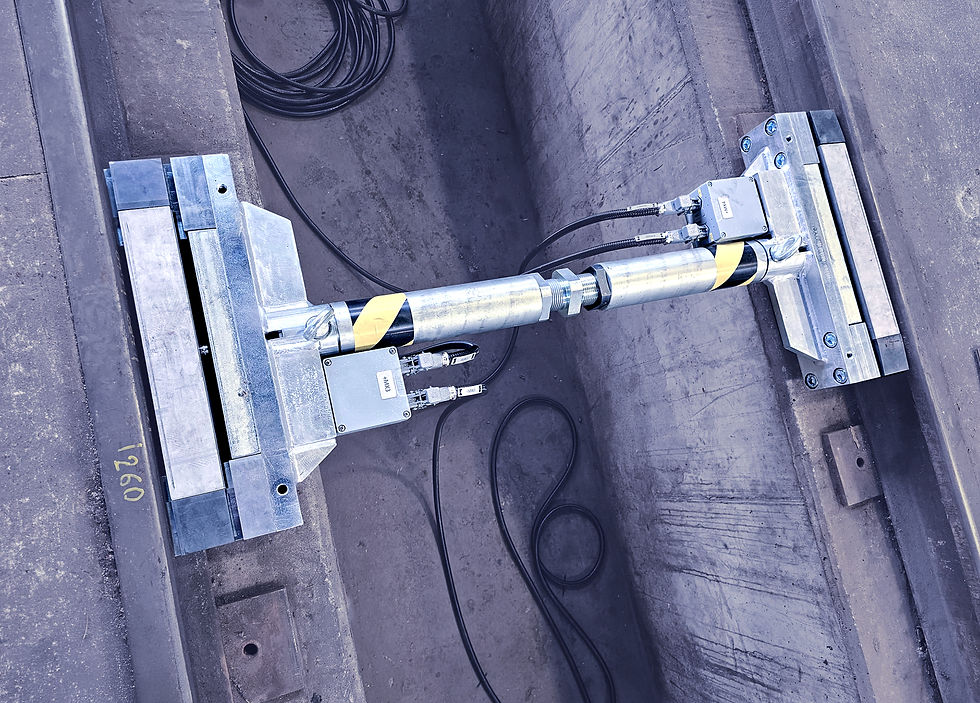

Balanced load on the wagon with a maximum deviation of 1-2%. Place the gauge where the wheel and rail touch each other. The portable scale will show you the weight of the wheel pressing on the rail. Adjust the axle pressure on the spot with a wireless tablet.

The scale measures very accurately - we had the results certified based on tests conducted in real conditions.

Key features

Train weight control

If you need to monitor the maximum permissible weight of freight trains.

Maintenance and inspection

When you want to be sure that your rolling stock does not damage the tracks (or other railway infrastructure)

Data collection for logistics

Scales help you distribute the load evenly throughout the wagon and speed up loading and unloading.

Load measurement

Evenly loaded wagons are stable during travel and reduce the risk of accidents caused by poor load distribution.

Technical parameters

Technicians work with a portable wireless tablet. With it, they can walk around the train or train set and, if necessary, adjust the pressure on individual axles.

Scale sensors are resistant to mechanical stress – they are not affected by braking forces or vibrations.

The scales work automatically with PLC, PC and HMI weighing software. You run it on the panel, including visualizations.

We supply 4 weighbridges as standard. You can also connect them in series to weigh four or more axles simultaneously.

In addition to the scale, we will also provide you with modifications to the project documentation that are necessary for its proper installation and operation in your operation.

Operators can finally work wirelessly and without worrying about damaging cables when moving the wagons. We solved this problem by wirelessly connecting the assembly pit to a laptop placed in the assembly table.

15+

tons

Maximum load per 1 measuring segment

1-2%

deviation

III Accuracy class (according to ČSN EN 45501)

4

weighbridges

Part of the basic equipment

Weighing date and time

Measurement location (e.g. specific track, odometer)

Vehicle number (e.g. train or wagon number)

Type of vehicle (truck, passenger car, etc.)

Type of mobile scale used (e.g. axle or total scale)

Location of weighing sensors (where the scales were installed on the rails)

Device calibration (confirmation that the device has been properly calibrated before use)

Axle weight and total vehicle weight

Load on individual wheels or axles

If the weight of several vehicles is measured, the weight of each of them is reported.

Verification that the results comply with the permitted limits (e.g. maximum axle weight or total train weight)

Record of any weight limit exceedance (if any)

Condition of rail infrastructure at the measurement location

Weather and other environmental factors that could affect measurements

Contact details of the person who performed the measurement

Signature and identification data of the person responsible for the measurement

Conclusions on compliance or non-compliance with regulations and safety standards

Recommendations for fleet maintenance or modifications (if excess weight or other parameter has been detected)

Measurement protocol

After the measurement, the software automatically issues you a report

After the measurement, don't forget to create an official record: for review, analysis, or if you need to verify that the measurement was done correctly. Our software will complete it for you automatically. The report contains these six parts:

Other technical parameters of the scales

Maximum load per 1 measuring segment

15,000 kg or more (according to specifications)

Maximum load per 1 measuring bridge

30,000 kg or more (according to specifications)

Verification piece

10 kg

Electrical connection

230 V(AC), 50 – 60 Hz

Operating temperature

-10°C – +40°C

Accuracy class

III (according to ČSN EN 45501

Rail types

S49 / S54 / UIC60

Knee height

28 – 32 mm