Key features

Saves space

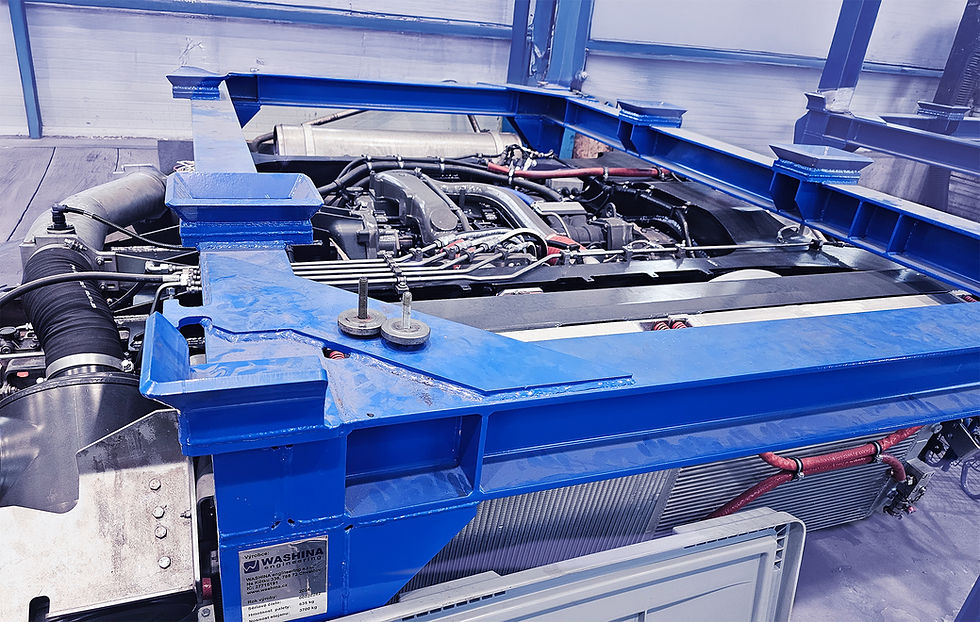

We designed the rack so that you can stack up to 3 powerpack units on top of each other. This saves space in the workshop and always gives you direct access to each motor.

Trial operation

You can test how the engine runs directly at the stand – even before installing it in the vehicle. This reduces vehicle downtime.

Safer work

The stands securely hold the powerpack and make it easier to transport it around the workshop. This prevents technicians from being injured when handling such heavy train components.

Protection against damage

Store the powerpack in a stand and protect the motor from damage due to improper handling or careless placement.

3

stands

You can stack up to 3 racks on top of each other

3.2×2.1

3,207 × 2,122 cm

Pallet size

D2866

MAN

For combustion engines of this type

Technical parameters

You can stack the racks on top of each other – up to three levels.

One stand holds one powerpack unit at a time.

The pallet dimensions are 3,207 x 2,122 centimeters, so you have enough space to handle the powerpack unit and store it safely.

The stand is suitable for the MAN D2866 combustion engine.